Dispersion of epoxy / alumina thermal conductive composite

Epoxy resin has many advantages, such as excellent adhesion, mechanical properties, electrical insulation, chemical stability, easy forming and processing, good stress transfer and low cost. It has been widely used in aerospace, electronic and electrical fields. With the development of electronic components towards miniaturization, integration and multi-function, higher requirements are put forward for the thermal conductivity of electronic components.

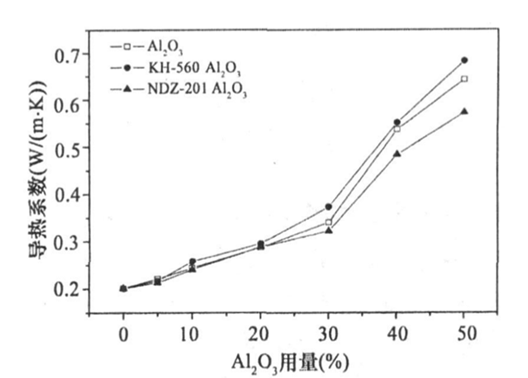

Aluminum oxide (Al2O3), silicon nitride (Si3N4), aluminum nitride (AlN) and silicon carbide (SIC) fillers have high thermal conductivity. The epoxy resin composite with good insulation can be obtained by filling and modifying the epoxy resin. The thermal conductive filler Al2O3 was modified by titanate coupling agent NDZ-201 and silane coupling agent KH-560, and the EP / Al2O3 thermal conductive composite was prepared by pouring method. The effects of Al2O3 dosage and coupling agent treatment on the mechanical properties and thermal conductivity of the composite were studied. The calculation model of thermal conductivity of EP / Al2O3 composite was discussed, which provided the basic theoretical basis for improving the thermal conductivity of EP / Al2O3 composite.

Experiment:

1、Main raw materials

Epoxy resin E-51, ethyl-4-methylimidazole, dimethylbenzylamine, alumina thermal conductivity 32W / (m · K), titanate coupling agent (NDZ-201), silane coupling agent (KH-560), acetone.

2、Method of EP / Al2O3 thermal conductive composite

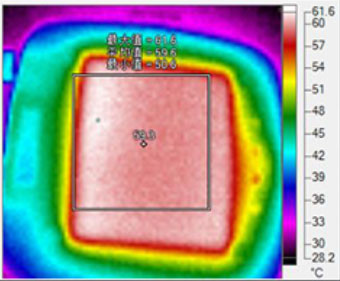

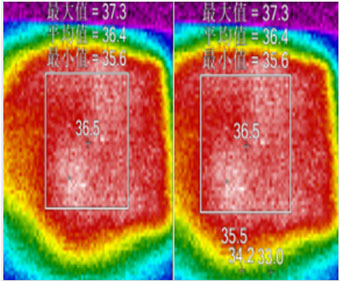

Take a certain amount of materials and put them into the mixing jar according to the proportion, and then use the ZYE Planetary Mixer to mixing and defoaming

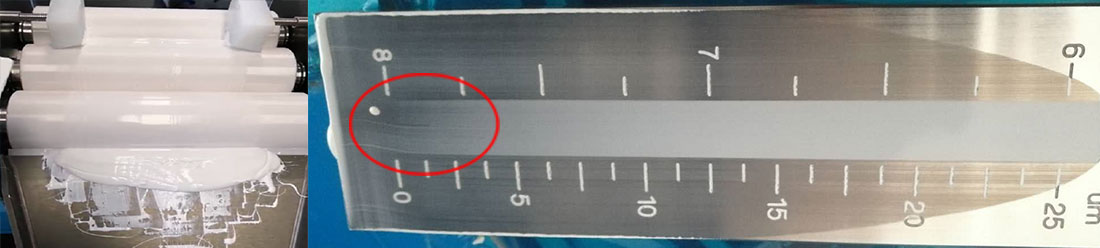

After mixing and defoaming, it is grinded and dispersed by ZYE three roller machine

The fineness of agglomerate is less than 5 μm after grinding by 80E three roller machine

3、Conclusion:

The thermal conductivity of EP / Al2O3 composite increases with the increase of Al2O3 content. When Al2O3 content is 50%, the thermal conductivity of the composite is 0.68w / (m · K); the bending strength and impact strength of the composite first increase and then decrease with the increase of Al2O3 content. When Al2O3 content is 5%, the mechanical properties of the composite is the best. The surface modification improves the thermal conductivity and mechanical properties of the material.

Since its high viscosity, it is difficult for traditional mixing and stirring to mix it evenly, and the bubbles are not easy to remove; at the same time, because of the high hardness of alumina, the traditional grinding method will rub the metal into debris and bring it into the material, causing pollution. The ZYE planetary mixer can solve the above problems well, mix the materials evenly and completely defoaming in vacuum environment; after grinding and dispersing by three roller machine, the thermal conductivity will be improved, and its stability will be greatly improved.